The novelty of owning a musical instrument is a treasured experience in its own right. The memory of unwrapping a brand new electric guitar in the form of a birthday present is ingrained in a child’s mind for many years. However, having this memory is not all inclusive for children around the world. The fact is, instruments are costly and not everyone has the opportunity to own them. Part of the reason is that making instruments is a complex craft that determines sound quality, playability, and aesthetic appearance, and with that comes a hefty price tag. However, with 3D printing technology, instruments can be readily available to the masses. The catch being these products will be made of plastic.

As of now, music companies are using 3D printing to model their designs before putting their instruments into production via injection molding or wood working. The plastic instrument models created lack the quality of a fully crafted product. However, they are still fully functional in terms of playability. The case is much more apparent in acoustic instruments such as a violin or an acoustic guitar, yet there is much more to explore with 3D printed electric instruments. These plastic instruments will not have the warmth and resonance of say an Ibanez hollow-body or a Gibson Les Paul, but with the advanced technology of present-day filters and mixers, sound quality can be fine-tuned.

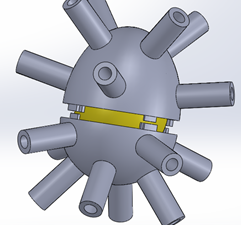

Fig 1: 3D Printed Electric Guitar by Odd Guitars

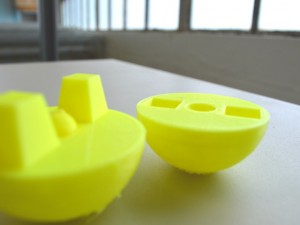

Desktop 3D Printing is still considered a novelty, and thus researchers and companies in the industry are experimenting with the capabilities of their machines. MIT Media Lab researcher Amit Zoran has created a working 3-D printed flute, printed all in one piece. Also, company EOS has created a printed violin that integrates traditional parts (i.e. the fine tuners, chin rest, bridge) with a plastic body. Now, sound quality aside, these instruments are not without mechanical flaws. There is a decently large margin of error in 3D printed parts, especially in the case of small components. For example, the printed flute contains keys that close poorly because of tolerance issues. But with further research and optimization, printing these instruments will be much more precise.

Fig 2: 3D Printed Violin

3D printing may extend even further into the realm of music. In addition to instruments, there is opportunity for integrating printed parts in the assemblies of MIDI keyboards, speakers, and recording equipment that are conventionally made with cast plastic parts. Not only will this decrease cost of production, but it will also enable more interchangeability for broken parts. As a musician, it is satisfying to see the interest for music spread throughout a population, and with the advent of 3D printed musical devices, there is no doubt that creating music will become more accessible.