Hypertherm Factory

The Scenario

Hypertherm is a 1,400 employee, New Hampshire-based company that designs and manufactures advanced plasma, laser and water jet cutting systems, cutting products, and related high-technology industrial applications used in a variety of industries including shipbuilding, manufacturing, and automotive repair. Hypertherm’s hundreds of thousands of customers, all over the globe, trust the performance and reliability of Hypertherm’s systems and enjoy the resulting increased productivity and profitability.

As an innovation company, Hypertherm uses 3D printing to rapidly produce models and prototypes for new product designs, as well as tooling for its manufacturing facility. The company was seeking to expand its usage of 3D printing, but its existing solution was not designed for use by groups and couldn’t keep pace. Users struggled with numerous issues:

- Submitting print jobs was extremely complicated.

- Predicting when the 3D printer would be available was difficult, since there was no way to know who was waiting to use it and when a print job was completed, other than going to the printer.

- Waiting for manual unloading of completed parts meant the 3D printers sat idle for long periods of time.

- Managing the 3D printer was quite difficult.

- Planning was difficult, due to the existing printer being unreliable and breaking down often, further delaying projects.

Hypertherm sought a new solution that was more suitable for a multi-user environment, with a need for innovation speed.

The Solution

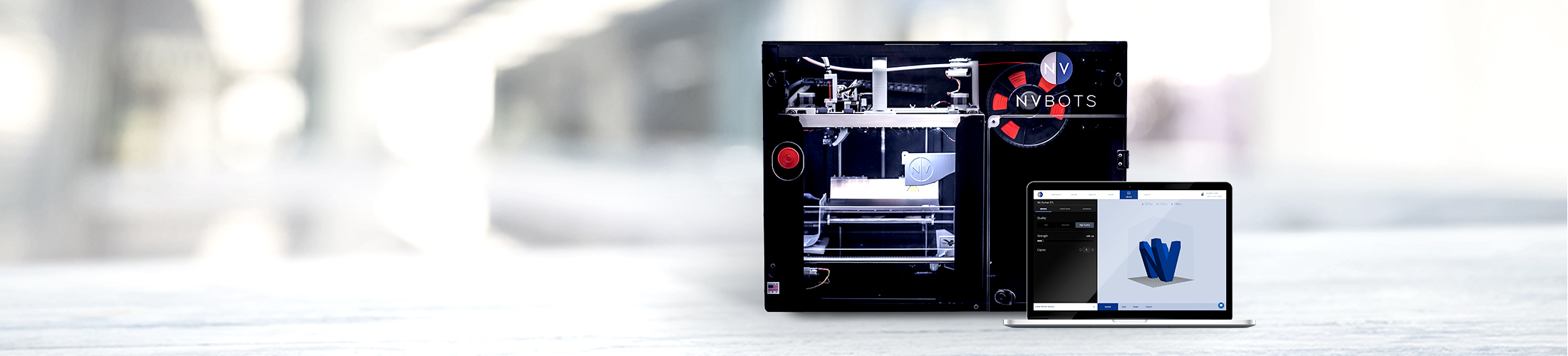

NVPro Automated 3D Printer

After evaluating numerous solutions, Hypertherm chose to purchase four NVBOTS’ NVPro 3D printers. The NVPro offers the only Built to Share™ automated part removal in the industry, and is paired with NVCloud software that allows users to print parts anytime, from any cloud-connected device – while providing administrators full control of print queues and workflows typical in a shared-use scenario. This combination of capabilities makes the NVPro uniquely suited for continuous 24×7 operation in multi-user environments. In particular, Hypertherm has been able to benefit from being able to:

- Submit jobs via NVCloud at any time – 24×7

- Eliminate the need for a printer operator, based on the NVPro’s automated part removal capability

- Scale to meet the growing user base, based on the shareability of the NVPro

- Benefit from a reliable printer supported by a responsive services team

The Results

The Built to Share™ NVPro increased Hypertherm’s use of additive manufacturing across the company, accelerating Hypertherm’s pace of new product design and innovation. The cloud-connected solution allows associates to easily develop and submit new part designs. The printers run 24-7, and do not require manual intervention to load and unload parts. Administrators manage the machines and print queues remotely, reducing their workload. The NVBOTS’ NVCare team supports the machines remotely, boosting reliability. The combination of capabilities has helped Hypertherm move 3D printing beyond narrow usage by a handful of experts. Today more than 100 employees use the printers to print over 50 parts per week, speeding their product development, resulting in faster time to market for their new products. Hypertherm also plans to take advantage of new 3D printer advancements coming out of NVBOTS, including the NVLABS multi-metal 3D printing technology.

“The NVPro is unique. It is Built to Share, and gives us a true 24-7, multi-user 3D printing capability. The NVCloud software makes it easy to submit new print jobs, and easy to manage our 3D printers. We use the remote video monitoring to confirm the printer is running and check part status. The automated part removal allows the machine to run overnight and on weekends, greatly increasing throughput. With the NVPro, we have been able to move 3D printing from something that very few people could use to something used widely with very little workload for administrators”.Cliff Darrow, Engineering Manager at Hypertherm