“What are you doing this summer?”

“I’m working for a 3D printing start-up.”

(awe)

What starts off as a typical conversation for a college student visiting home, evolves into a playful interrogation. In that moment, the responsibility for answering every question they’ve ever had about 3D printing falls on me. Some people are only mildly curious, wanting a basic understanding of how 3D printers work and what they can make. Others want to know everything they possibly can about 3D printers, which is stressful to convey. Hopefully, this clarifies some of the basics:

3D Printing: a term used by the media to refer to almost all forms of additive manufacturing. The term was trademarked in the 90s to refer to a specific type of additive manufacturing, which I will not go into here. Usually when people say they 3D printed something, they made the object using fused filament fabrication, described below.

Additive Manufacturing: a process in which a part is built by adding material rather than removing it. Most manufacturing involves removing material similar to the way a sculptor chips away at a block of marble to create a statue.

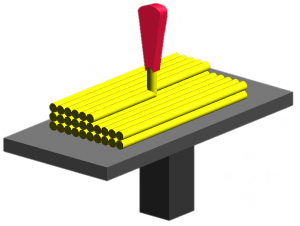

Fused Filament Fabrication (FFF): a type of additive manufacturing in which objects are built up by laying down layers of hot plastic. It’s the same thing as Fused Deposition Modeling (FDM).

The rest of this article is about FFF printing since that’s what I work with on a regular basis.

The definition above is formal and dry. Since it is commonly referred to as 3D printing, I like to make direct comparisons to the standard inkjet printers. Imagine that a 3D printer is simply a normal printer where instead of printing ink, it prints plastic. Recall how an ink printer moves in a 2 dimensional plane, across the paper and down the paper. Now imagine that a 3D printer can do that, but it can also move up. So, once the 3D printer has printed the first layer of plastic, it moves up a little and prints another layer of plastic on top of the first layer.

Image depicting the layered nature of FFF printers. Created by Zureks.

The plastic is partially melted allowing it to flow from the nozzle and stick to the layer below it. Once the plastic leaves the nozzle, it begins to cool which hardens the plastic. The printer head must put down an entire layer of plastic before it can move on to the next layer. There is a delicate balance the speed of the printer head and the rate the plastic cools. If the plastic cools too much, the layers won’t adhere nicely to each other; if the plastic is too melted the next layer won’t be well supported.

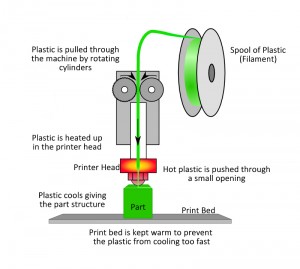

The image below visually describes the basic mechanics of how FFF printers work. It is a modified version of a picture found on the RepRap site.

1 Comment

-

Wow, wonderful blog layout! How long have you been blogging for?

you made blogging look easy. The overall look of your website is fantastic, let alone the content!