3D printing has quickly taken many industries by storm, and sporting goods and sportswear is no exception. Large companies such as Nike and New Balance are beginning to recognize the potential of 3D printing and integrate the technology into their products. The characteristics of 3D printing that make it such a popular form of manufacturing for many industries also translate well to the sporting goods industry. Companies are able to rapidly prototype their new designs before going into full production. Additionally, 3D printing offers the ability for top athletes to receive custom made gear that fits them perfectly.

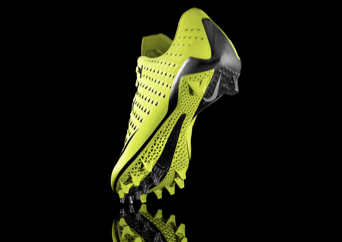

Recently, in preparation for the 2014 FIFA World Cup, Nike unveiled a 3D printed sports bag that will be given to certain marquis players. The Nike Football Rebento is the first 3D printed football bag. The bag itself is covered in a nylon mesh that was printed using laser-sintering. Additionally, Nike also provided the players 3D-printed shin guards, which take advantage of the technology to create a new type of shock absorbing system that uses a honeycomb pattern, rather than foam. Nike also integrated 3D printing with its football cleats and again gave out their products to top athletes in order to promote them. During the NFL combine, Nike outfitted many of the top college football players with their new Nike Vapor Laser Talon. The bottom plate of the shoe was 3D printed using laser sintering and was designed to optimize an athlete’s performance on the forty yard dash, one of the most important events of the combine. New Balance quickly followed with a similar design for their running spikes. Nike cites the ability to rapidly prototype as the main advantage of developing 3D printed technologies.

Other popular sporting goods companies also take advantage of 3D printing during prototyping. Burton, for example, 3D prints prototype snowboard bindings so they may quickly fabricate a design for testing. In the near future, we will likely see production bindings that are 3D printed. Many Formula 1 racing teams also utilize 3D printing, a model of a body design or feature can be manufactured quickly and then utilized for wind tunnel testing.

The spread of 3D printing technology has enabled many top athletes in a variety of sports to utilize custom equipment that is specifically tailored to their body and needs. Trek, a bicycle company, has stated that it uses 3D printing frequently whilst prototyping. Additionally, Trek offers top athletes custom made helmets that are printed specifically for the athletes head, based on a 3D scan. In a similar vein, Speedo, a swimwear company, outfits its Olympians with custom 3D printed goggles that are designed to fit perfectly on the swimmer’s face.

Large sporting goods companies are not the only ones taking advantage of 3D printing technology. Helico, a startup, has created AirDog, a quadcopter drone that follows one around and films them. The body of the copter was 3D printed with a specialized plastic that is ubiquitous in the aerospace industry. The user wears a bracelet and the copter tracks them while they do their chosen activity, whether it is surfing or skiing.

3D printing is becoming prominent in every industry, and the sporting goods sector is no exception. Although the technology is currently used for nothing more than customization and promotion, I suspect that soon companies will begin to mass manufacture 3D printed sporting goods.