Customers to Benefit from Growing List of Supported Metals, Including Stainless Steel, Titanium, Nickel, Copper Nickel, Aluminum, Zirconium, Silver and Palladium.

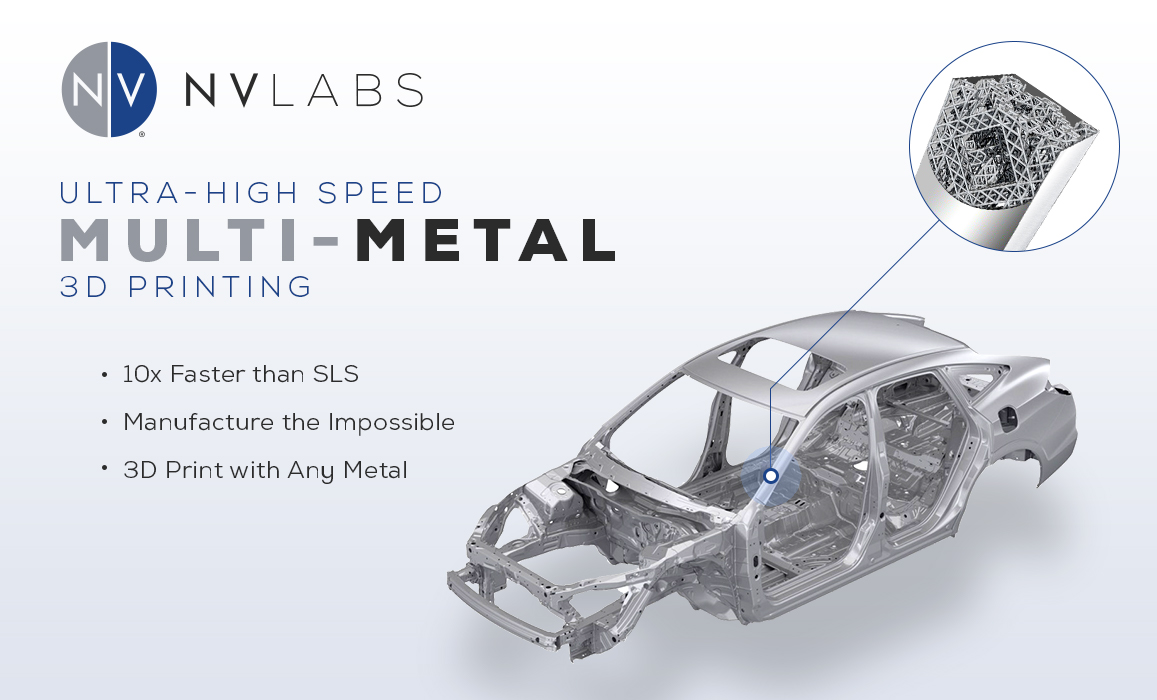

BOSTON, MA - (January 21, 2016) – NVBOTS, the provider of automated, enterprise 3D printing solutions disrupting business and education, today announced it has established NVLABS, dedicated to meeting the needs of any company seeking to commercialize their innovations through ultra high-speed, multi-metal 3D printing. Based on the only 3D printing technology that can print multiple metals in the same build, NVBOTS enables companies to capitalize on 3D printing opportunities related to a growing list of metals that includes stainless steel, titanium, nickel, copper nickel, aluminum, zirconium, silver and palladium.

NVBOTS has also appointed Dr. Paul Burke to the role of Chief Research Officer. A renowned metallurgy expert, Dr. Paul Burke now leads NVLABS R&D efforts, commercial projects and innovations. Combining deep 3D printing and metallurgy expertise with breakthrough, patented technology, NVLABS is set to transform the way companies deliver their innovations to the marketplace.

“As NVBOTS has evolved, our core focus has always been around a three-part evolution: education, innovation and commercialization,” said NVBOTS CEO AJ Perez. “Through the establishment of NVLABS and bringing on Dr. Paul Burke, we are breaking new ground in enterprise 3D printing, through unmatched multi-metal printing capabilities, allowing companies on a global scale to commercialize their innovations in ways never before thought possible.”

Focused on enabling enterprises and Fortune 500 companies to deliver on their engineering innovations through ultra high-speed, multi-metal 3D printing capabilities, NVLABS will empower these companies to print over 10x faster than existing solutions – and at a significant cost advantage. Companies taking advantage of NVLABS will benefit from new innovations based on accelerated metals testing and engineering of designs which will dramatically improve efficiencies related to assembly and performance. Chief Research Officer Dr. Paul Burke will oversee all NVLABS-sponsored projects and future innovations based on the NVBOTS patented technology platforms.

“3D printing is undergoing a transformative state and NVBOTS has been leading the way since the development of the world’s first fully automated 3D printer, able to run 24×7 without human interaction – essentially providing a 6 square foot automated factory in a box,” said Dr. Paul Burke. “With NVLABS, the company is set to take things to an entirely new level, granting companies access to state-of-the-art automation and ultra high-speed, multi-metal printing capabilities that will allow them to cost-effectively manufacture and scale, in ways only imaged – until now. I am proud to be part of such a well-respected and progressive company, and I look forward to making a difference in the world through our efforts.”

An undisputed metals visionary and expert in sintering, Dr. Burke was recently the Lead Researcher and Project Manager at Group Sadoway, working with well-known electrochemistry expert Professor Donald R. Sadoway. Holding numerous positions at the Massachusetts Institute of Technology (MIT), Dr. Burke has successfully led research teams focused on areas such as Liquid Metal Battery, Electrochemical Studies and Automotive body sheet alloys. Dr. Burke has also held positions at Ambri Inc., Dalhousie University, Novelis Inc., Luxfer Gas Cylinders and Interactive Toy Concepts. Dr. Burke received a PhD in Materials and Metallurgical Engineering, as well as a Masters of Applied Science, Materials and Metallurgical Engineering, at Dalhousie University.

“Since our inception, NVBOTS has been committed to transforming education and business through a truly disruptive approach to 3D printing,” said NVBOTS CTO Forrest Pieper. “Through the establishment of NVLABS and bringing on a known metals thought leader like Dr. Burke, we continue to challenge the status quo, fundamentally transforming 3D Printing in new and exciting ways.”

About NVBOTS

Passionate about problem solving, NVBOTS is the provider of automated, enterprise 3D printing solutions disrupting business and education. NVBOTS customers are able to benefit from ultra high-speed, multi-metal and plastics printing capabilities, based on patented 3D printing technology (coming out of NVLABS). Offering the only 3D printing technology that can print multiple metals in the same build, NVBOTS supports a growing list of metals that includes stainless steel, titanium, nickel, copper nickel, aluminum, zirconium, silver and palladium. With NVBOTS, users can print over 10x faster than existing solutions – and at a significant cost advantage. Essentially an automated factory in a box, the company’s easy-to-use and easy-to- share 3D printing experience is based on the NVPro, the world’s first end-to-end 3D printing solution with automated part removal. Paired with the NVBOTS cloud-based interface, the NVPro runs continuously, 24-7 from any device. The company is headquartered in Boston, MA. For more information, visit www.NVBOTS.com or follow us on Twitter @NVBOTS and on LinkedIn.

Contacts

AJ Perez, CEO

New Valence Robotics Corporation

[email protected]

857-317-3130

Jennifer Meyer, for NVBOTS

[email protected]

603-508-0551