A Factory at Your Fingertips

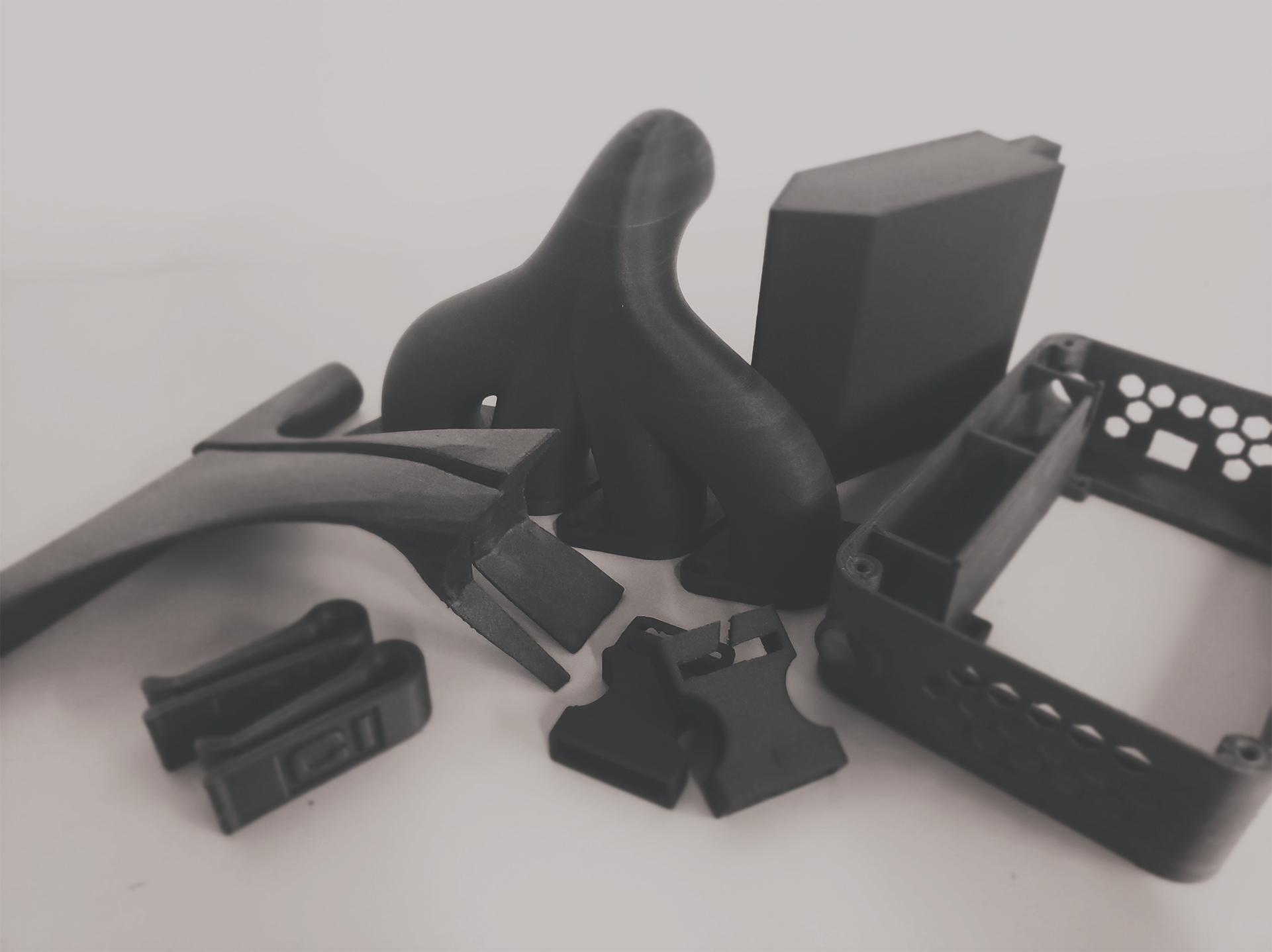

Bring Ideas to Life with 3D Printing

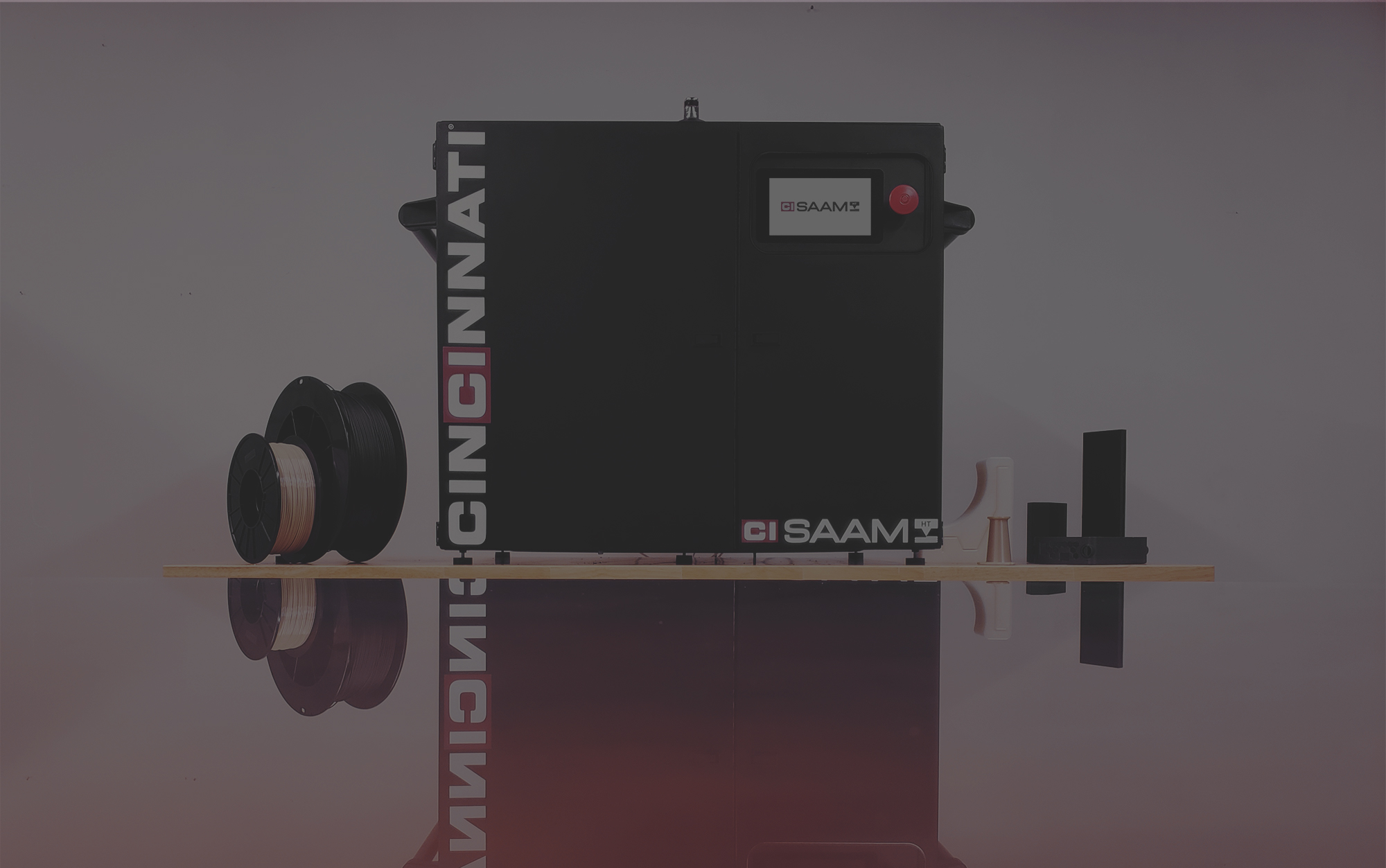

From the Lab to the Factory Floor

3D Printing Isn’t Just For Prototyping

Production Planning

Simple drag-and-drop interface helps you prioritize what matters.

No Labor Required

Automated part ejection reduces production costs by 1000%.

Built for Reliability

Made in America (so you know it’s good).

NVCloud Submissions

Labor Hours Saved

3D Printing Meets Mass Production

Produce batches of more than 50,000 economically.